Polymer Compounding

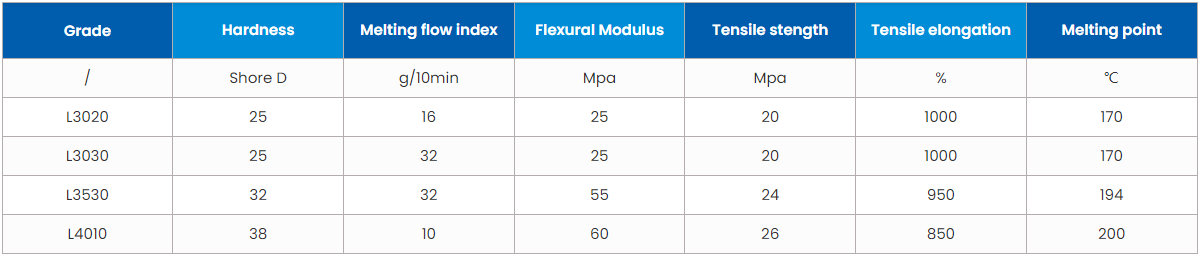

KYLflex® TPC-ET/TPEE has good flexibility, high melt stability and low melt viscosity. It can be used to improve the impact strength (toughness) at high and low temperature , flexibility and blending compatibility of plastics. It is mainly used for modification TPE, POM, PET, PBT, PVC, etc.